Coriolis Flow Meters

Mass Flow Rate Measurement For Liquids & Gases

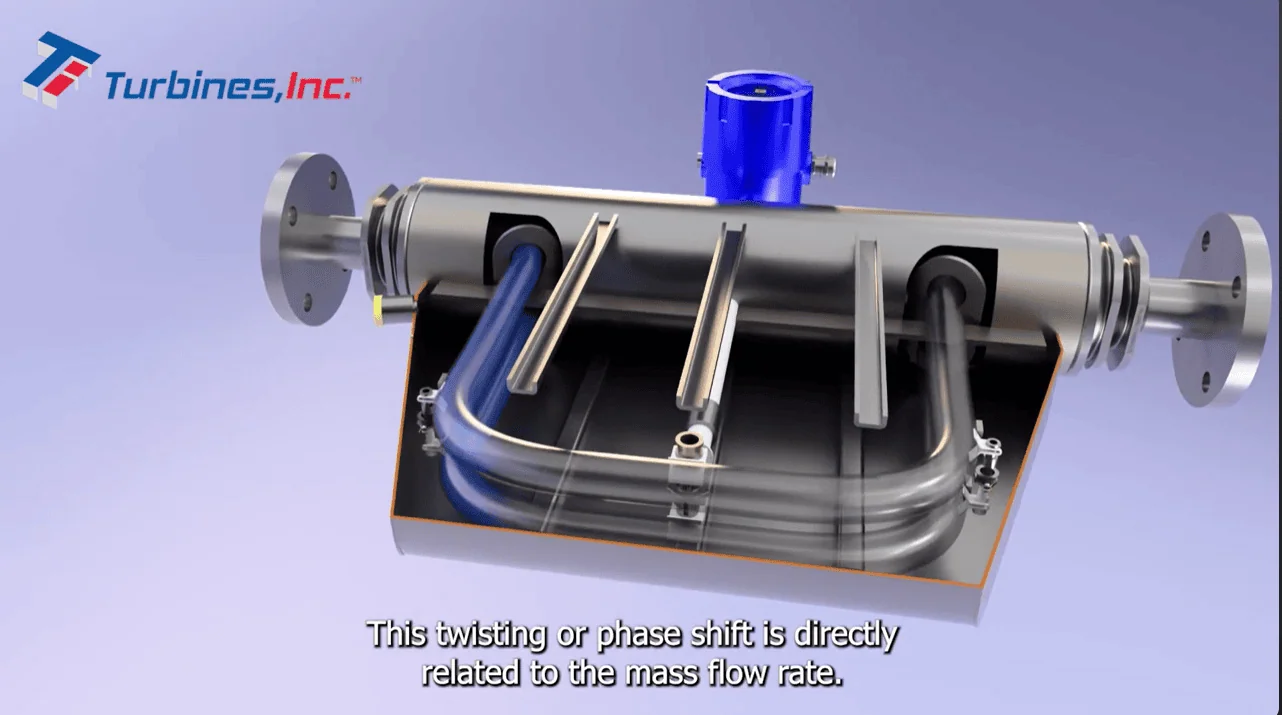

Coriolis mass flow meters are renowned for their exceptional accuracy and direct mass flow measurement capabilities, making them ideal for a wide range of industrial applications. These advanced meters measure both mass flow and density in real time, providing critical insights for processes involving liquids, slurries, and gases. With no moving parts and minimal maintenance requirements, these meters offer long-term reliability in demanding environments such as chemical processing, food and beverage, oil and gas, and pharmaceutical manufacturing. Available in a variety of sizes and configurations, these meters deliver precise performance for both low- and high-flow applications.

Product Catalog

Need To See More Flow Meters?

View All ProductsNeed help finding a flow meter?

We can help guide you to the correct solution for your business needs, whether you are looking for product information, data sheets, repair information we are available to help!