Flow Meters

Precision Focused Flow Measurement Solutions

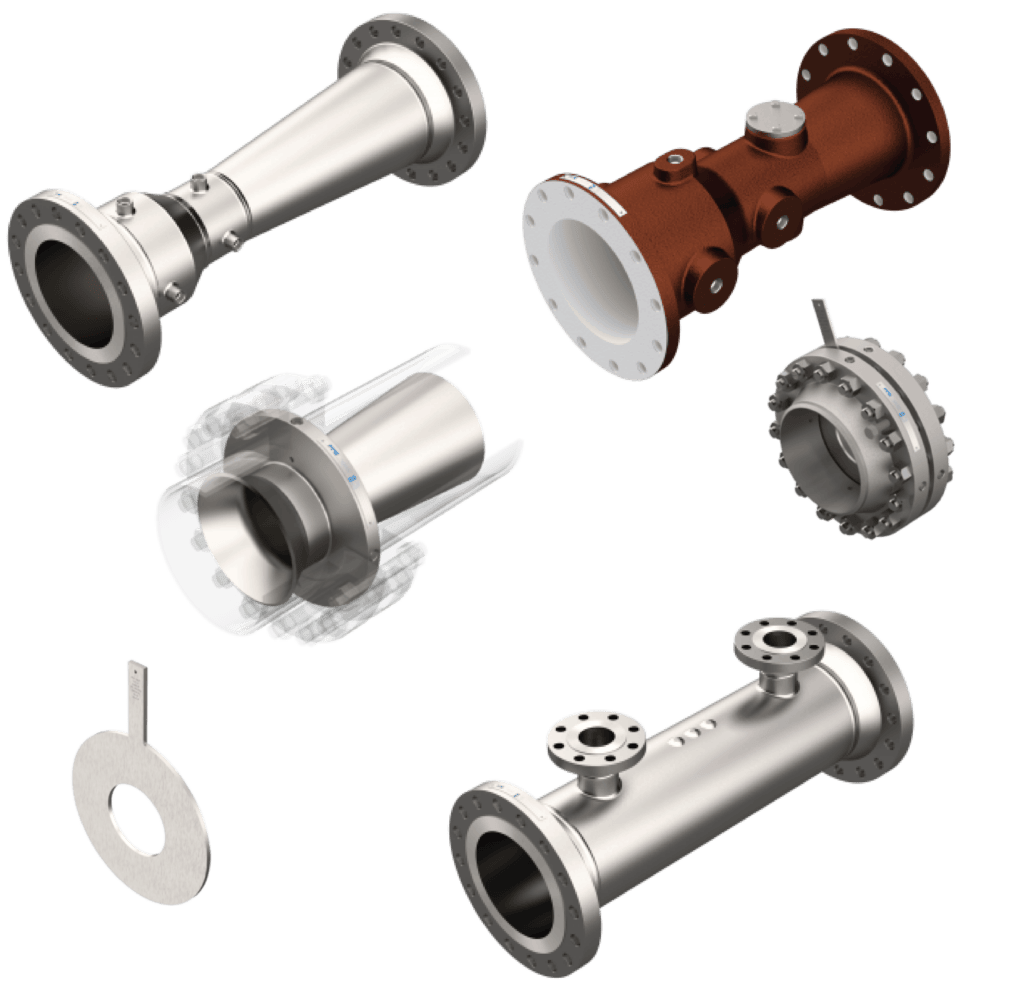

Turbines, Inc. manufactures and supplies a diverse range of precision-engineered flow meters—including turbine, Coriolis, and differential pressure models—designed to meet the exacting standards of industries such as oil and gas, chemical processing, aerospace, and cryogenics, with each meter type offering distinct advantages for measuring flow rate, density, or pressure drop across a wide range of fluids; backed by decades of expertise, U.S.-based production, and a commitment to accuracy, durability, and customer support, Turbines, Inc. ensures dependable performance in even the most demanding flow measurement applications.

Understanding Different Flow Measurement Technologies

Flow measurement involves tracking the movement of fluids through pipes and systems within industrial or plant settings. A range of instruments can be used to measure flow, including Turbine, Coriolis, Differential Pressure, and more.

Not Sure Where to Start?

We can help guide you to the correct solution for your business needs, whether you are looking for product information, data sheets, repair information we are available to help!