When accuracy and reliability are non-negotiable, engineers often narrow their flow-meter options down to two proven technologies: positive displacement (PD) and turbine flow meters. Both deliver exceptional measurement performance, but each is designed for different conditions, fluid types, and operating environments. Selecting the right one can directly impact efficiency, cost, and product quality. In this…

Key Flow Metering Challenges in Cryogenic Applications

- News

Cryogenic fluids such as liquefied natural gas (LNG), liquid hydrogen, and liquid nitrogen are at the center of today’s energy transition and industrial gas supply chain. They allow gases to be stored and transported in dense liquid form, but the extremely low temperatures required for cryogenic storage bring unique engineering challenges. When measuring the flow…

Flow Meter Communication Protocols Explained: 4–20 mA, MODBUS, HART, RS232, and More

- News

Why Communication Protocols Matter in Flow Measurement In modern process industries, flow meters are more than just instruments that measure liquid or gas movement. They are a critical part of the control loop, sending data to supervisory systems, PLCs, and SCADA platforms. Accurate and reliable communication ensures that process decisions are based on trustworthy information….

Field Troubleshooting: Diagnosing Common Issues with Turbine Flow Meters

- News

Turbine flow meters are trusted instruments across industries that need accurate and repeatable flow measurement. From custody transfer of fuels to monitoring water treatment processes, turbine meters offer a proven balance of precision, simplicity, and durability. Yet like any mechanical or electronic device, their performance can decline over time if conditions change, if components wear,…

Total Cost of Ownership: Why Turbine Meters Are More Cost-Effective Than You Think

- News

When it comes to choosing a flow meter, most buyers start with the most visible factor: the purchase price. At first glance, that’s a logical place to begin—budgets matter, and procurement teams are always looking for ways to control costs. But here’s the catch: the sticker price tells only a small part of the story….

Choosing the Right Flow Meter for Harsh Oil & Gas Environments

- News

In the oil and gas industry, accurate flow measurement is critical for safety, compliance, and profitability. Every barrel of crude oil, every cubic foot of natural gas, and every gallon of refined product represents significant value. Errors in measurement can quickly lead to disputes, revenue loss, or regulatory issues. Harsh operating conditions make flow measurement…

How Temperature, Pressure, and Viscosity Affect Flow Measurement

- News

Imagine this: an engineer is reviewing flow data from a custody transfer application. The flow meter in use is a high-quality, precision-calibrated unit. Yet, the readings fluctuate more than expected. The equipment appears to be functioning correctly, but the numbers are still off. In many cases, the issue is not the flow meter itself but…

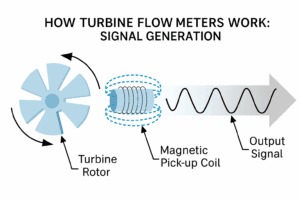

How Turbine Flow Meters Work: Inside the Engineering

- News

When it comes to accurate and repeatable flow measurement in demanding industries, turbine flow meters have stood the test of time. Known for their high precision and robust construction, these meters are trusted in everything from aerospace fuel systems to cryogenic liquid transfer. But what exactly makes them work, and why do engineers continue to…

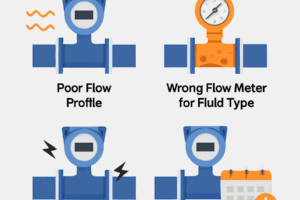

Common Flow Meter Errors and How to Avoid Them

- News

Accurate flow measurement is critical across a wide range of industries—from oil and gas to food and beverage, pharmaceuticals, and chemical processing. Yet even the most advanced flow meter can produce inaccurate readings if it’s installed incorrectly, applied in the wrong conditions, or left unmaintained. These common mistakes not only compromise measurement accuracy, but they…

Building a Flow Measurement System

- News

Flow meters—whether turbine, Coriolis, electromagnetic, or ultrasonic, are designed to measure the movement of fluid through a pipe. But the raw flow reading doesn’t always represent the actual volume or mass of fluid being transferred, especially when temperature or pressure fluctuations are involved. For instance, in gas applications, both temperature and pressure have a direct…