Why Communication Protocols Matter in Flow Measurement

In modern process industries, flow meters are more than just instruments that measure liquid or gas movement. They are a critical part of the control loop, sending data to supervisory systems, PLCs, and SCADA platforms. Accurate and reliable communication ensures that process decisions are based on trustworthy information. Without the right communication protocol, even the best flow meter cannot deliver its full value.

Engineers today face a wide range of communication standards to choose from, each with its own benefits and limitations. Some are simple analog signals that have been used for decades, while others are advanced digital protocols designed for Industry 4.0. Knowing the differences can help you select the right option for your application.

This guide walks through the most common flow meter communication methods used in engineering: 4–20 mA current loops, voltage outputs such as 0–5 V and 0–10 V, HART, MODBUS (RTU and TCP/IP), RS232, and RS485.

Analog Communication Standards in Flow Measurement

4–20 mA Current Loop

For more than 50 years, the 4–20 mA current loop has been the industry standard for transmitting flow data. The signal is based on a current that changes proportionally with the measured variable.

Why engineers choose 4–20 mA:

- Excellent noise immunity, even in electrically noisy environments

- Works over long cable runs, often up to 1,000 meters

- Simple two-wire loop configuration that also powers the transmitter

- Universally supported across flow meter manufacturers

Limitations:

- Only transmits one variable at a time

- Cannot carry additional diagnostic or configuration data without another protocol layered on top

Typical applications:

- Custody transfer of fuels and chemicals

- Pipeline monitoring

- Industrial processes where reliability is more important than advanced diagnostics

0–5 V and 0–10 V Voltage Outputs

Voltage outputs provide a proportional signal that represents flow. Although less common in heavy industry, they are still used in testing and laboratory environments.

Why engineers choose voltage signals:

- Low cost and easy to implement

- Suitable for short distances where electrical noise is minimal

- Can be connected to a wide range of data acquisition systems

Limitations:

- More susceptible to noise compared to current loops

- Not suitable for long cable runs

- Rarely used in modern large-scale industrial networks

Typical applications:

- Laboratory test benches

- Compact flow measurement systems

- Educational or training setups

Digital Communication Protocols for Flow Measurement

While analog signals are still widely used, digital communication protocols allow engineers to access more information than just flow rate. They can provide diagnostics, multiple variables, and flexible network integration.

HART (Highway Addressable Remote Transducer)

HART is a hybrid protocol that overlays digital communication on top of an existing 4–20 mA loop. This makes it backward compatible with older systems while enabling new functionality.

Why engineers choose HART:

- Transmits digital data without replacing existing 4–20 mA wiring

- Provides device diagnostics and configuration remotely

- Supports multiple process variables, not just flow rate

- Huge installed base across the process industries

Limitations:

- Slower communication speed compared to modern Ethernet protocols

- Requires HART-compatible transmitters and control systems

Typical applications:

- Process plants needing both analog reliability and digital diagnostics

- Smart instrumentation where remote calibration and configuration are important

MODBUS (RTU and TCP/IP)

MODBUS is one of the most widely adopted communication protocols in industrial automation. It is open, flexible, and simple to implement.

Two main forms of MODBUS are used with flow meters:

- MODBUS RTU (over RS485): Serial communication that supports multiple devices on a single network.

- MODBUS TCP/IP: Ethernet-based communication that integrates with modern industrial networks.

Why engineers choose MODBUS:

- Open protocol supported by almost all PLCs and SCADA systems

- Can connect many devices on one network

- Flexible and well-suited for supervisory control

Limitations:

- RTU is slower than Ethernet options

- Requires more setup than simple analog signals

- TCP/IP requires Ethernet infrastructure

Typical applications:

- Water and wastewater treatment plants

- Power generation and building automation

- Large process plants with multiple meters and devices

RS232 and RS485 Serial Standards

Before Ethernet became dominant, RS232 and RS485 were the backbone of industrial communication. They remain relevant as physical layers and for integration with legacy equipment.

RS232:

- Simple, point-to-point communication

- Short distance, typically less than 15 meters

- Still found in direct connections between a meter and a PC

RS485:

- Multi-drop communication for up to 32 devices

- Much longer range than RS232, up to 1,200 meters

- Commonly used as the physical layer for MODBUS RTU

Why engineers still see RS232/RS485 today:

- Legacy installations where replacing hardware is costly

- Simple, reliable setups that do not require Ethernet

- Distributed flow meters in facilities where MODBUS RTU is used

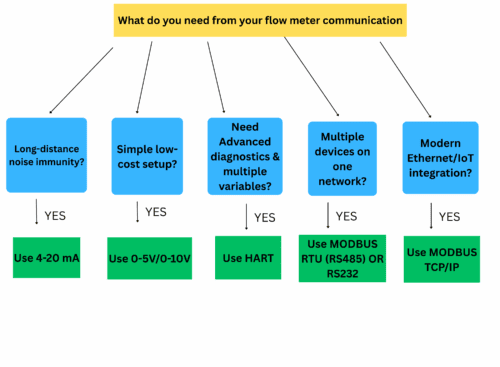

Choosing the Right Communication Protocol: An Engineer’s Guide

Selecting the right communication protocol is not a matter of which one is best overall. It depends entirely on the application, environment, and system requirements.

Factors to consider:

- Distance and noise: Current loops (4–20 mA) excel in long-distance and high-noise environments.

- Number of devices: RS485 or MODBUS is ideal when multiple flow meters must share a network.

- Data requirements: HART or MODBUS is better if you need more than just flow rate.

- System compatibility: Ethernet-based MODBUS TCP/IP is future-proof, but legacy systems may require analog or serial options.

Practical examples:

- Remote pipeline with long distances: 4–20 mA

- Small laboratory test setup: 0–10 V

- Process plant with diagnostics: HART

- Multi-device industrial network: MODBUS RTU or TCP/IP

- Legacy device connection: RS232

To help simplify this decision, a comparison chart is useful.

Flow Meter Communication Protocol Comparison

|

Protocol / Signal |

Type | Pros | Cons | Best Use Cases |

|

4–20 mA |

Analog (Current) |

Noise immune, long-distance capable, simple wiring | Only one variable |

Pipelines, custody transfer |

|

0–5 V / 0–10 V |

Analog (Voltage) | Low cost, simple setup | Noise sensitive, short range |

Lab setups, testing |

|

HART |

Digital + Analog | Diagnostics, multi-variable, backward compatible | Slow, requires HART devices | Smart process plants |

| MODBUS RTU (RS485) | Digital (Serial) | Multi-device, widely supported | Older, slower |

SCADA/DCS systems |

|

MODBUS TCP/IP |

Digital (Ethernet) | Fast, scalable, Industry 4.0 ready | Needs Ethernet |

Modern industrial plants |

|

RS232 |

Digital (Serial) | Simple, point-to-point | Very short range |

Legacy PC connections |

|

RS485 |

Digital (Serial) | Long distance, multi-drop | Often only physical layer |

Distributed networks |

Emerging Trends in Flow Meter Communication

The industrial world is shifting rapidly toward Ethernet and IoT solutions. Engineers should keep an eye on new protocols that are becoming more common in flow measurement:

- EtherNet/IP, PROFINET, and OPC UA are increasingly supported in advanced flow transmitters.

- Wireless technologies such as Bluetooth and Wi-Fi are making portable or remote diagnostics easier.

- IoT integration allows real-time flow data to feed into predictive maintenance and cloud analytics.

While analog signals will continue to be relevant, particularly in harsh and remote environments, digital and Ethernet-based protocols are becoming the new standard for connected industries.

Which Communication Is Right For You?

Communication protocols are just as important as the flow meter itself. They determine how easily data can be transmitted, how many devices can be connected, and whether diagnostics and advanced information are available.

There is no one-size-fits-all solution. Engineers must evaluate the environment, data requirements, and existing infrastructure when specifying a flow meter. A laboratory setup might only require a simple 0–10 V signal, while a large refinery may benefit from a MODBUS TCP/IP network with Ethernet connectivity.

By understanding the differences between 4–20 mA, HART, MODBUS, RS232, RS485, and voltage outputs, engineers can design flow measurement systems that are both reliable and future-ready.