When specifying or installing a flow meter, orientation might seem like an afterthought. After all, if the meter is inline and the fluid is moving, shouldn’t it work the same regardless of how it’s mounted? In reality, the way a flow meter is positioned—whether vertically, horizontally, or at a custom angle—can significantly influence measurement accuracy, long-term performance, and even meter lifespan.

Understanding the importance of proper orientation will help you avoid costly measurement errors, misdiagnosed maintenance issues, and even failed compliance checks. Let’s break down how orientation affects different types of flow meters and what you need to consider for optimal installation.

Why Orientation Affects Flow Meter Performance

Flow meters are engineered to operate under specific fluid dynamics. The effects of gravity, pressure, and flow behavior vary depending on orientation and fluid type. Components like floats, rotors, sensors, or transducers often rely on stable flow profiles or gravitational alignment to function correctly.

For example, variable area meters (rotameters) depend on gravity to balance the float against flow pressure. Turbine meters require laminar flow profiles, which can be distorted by improper piping layouts or entrained air pockets. Inaccurate installation orientation can result in turbulence, cavitation, vapor lock, or sediment buildup—all of which degrade performance.

Vertical Orientation

When It’s Recommended

Vertical orientation is commonly used in applications involving variable area flow meters or systems where gravity assists in measurement. It’s particularly useful when fluid needs to drain naturally or when you’re working with clean-in-place (CIP) systems in pharmaceutical or food applications.

Pros

- Supports gravity-based measurement devices

- Minimizes air bubble accumulation in liquid systems

- Provides easier visual float reading in rotameters

- Facilitates self-draining for sanitary systems

Considerations

Vertical orientation requires that flow direction is bottom-to-top. If flow direction is reversed or inconsistent, readings can be skewed. It’s also less suitable for applications with pulsating flows, as rapid flow fluctuations may destabilize internal components like floats.

Horizontal Orientation

When It’s Recommended

Horizontal orientation is standard for many inline flow meters including turbine, electromagnetic, and ultrasonic meters. It aligns well with most industrial piping layouts, offering straightforward installation and maintenance access.

Pros

- Compatible with common process piping systems

- Provides a stable support base for heavier meters

- Simplifies installation using flanged or threaded pipe connections

Considerations Air entrapment in liquid systems is a common issue in horizontal installations. Gas bubbles may accumulate at the top of the pipe, causing reading errors. Some flow meters must be installed at a specific height or position within the piping run to maintain accuracy.

Custom or Angled Orientation

When It’s Necessary

Certain applications, such as compact skid systems, mobile units, or retrofit projects, may require mounting the flow meter at a non-standard angle. In such cases, custom or angled orientations might be unavoidable.

Risks

- Measurement inaccuracies due to altered flow profiles

- Voiding manufacturer warranties if guidelines aren’t followed

- Internal parts may wear unevenly, reducing meter life

How to Make It Work

To mitigate risks:

- Consult your flow meter’s manufacturer for specific mounting guidelines

- Use flow straighteners or flow conditioning elements if turbulence is a concern

- Where available, use compensation software to adjust for off-axis installation effects

Manufacturer Guidance & Datasheet Clues

Flow meter manufacturers include detailed installation instructions in datasheets and user manuals. These documents often contain orientation arrows, preferred flow directions, and minimum straight-run pipe lengths before and after the meter.

Ignoring these recommendations can reduce meter accuracy or lead to non-compliance with regulatory standards like ISO, ASME, or API. Always refer to the OEM documentation, and if your application requires deviation, consult the manufacturer directly.

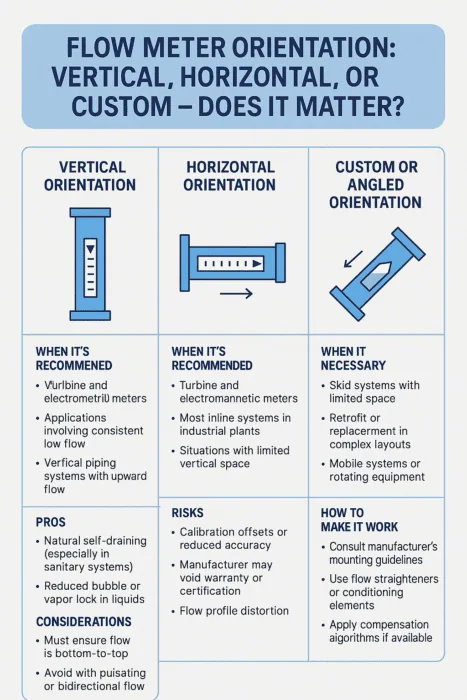

Infographic: Flow Meter Orientation Quick Guide

Vertical Orientation:

- Best for: Rotameters, sanitary CIP systems

- Flow Direction: Bottom-to-top

- Pros: Gravity-assisted, self-draining, bubble minimization

- Watch Out For: Pulsating flow, reversed flow

Horizontal Orientation:

- Best for: Turbine, magnetic, ultrasonic meters

- Flow Direction: Left-to-right (or as specified)

- Pros: Stable install, integrates with standard piping

- Watch Out For: Gas bubbles, improper alignment

Custom Angled Orientation:

- Best for: Space-restricted or skid-mounted systems

- Flow Direction: Application-specific

- Pros: Design flexibility

- Watch Out For: Measurement drift, warranty limits, unapproved installs

Choosing the Right Orientation

Here are a few key factors to help guide orientation decisions:

- Fluid Type: Gas systems tend to be more orientation-sensitive due to compressibility and buoyancy effects. Liquid systems may accumulate vapor or air pockets depending on orientation.

- Meter Technology: Some meters (e.g. Coriolis) are less sensitive to orientation, while others (e.g. variable area) require strict alignment.

- Installation Environment: Tight spaces or mobile systems might limit orientation options. Always weigh flexibility against performance.

- Maintenance Access: Consider which orientation provides better visibility and serviceability.

- Compliance Requirements: For regulated applications, follow installation instructions exactly to ensure traceable, verifiable readings.

Final Thoughts

Orientation isn’t just a minor detail—it’s a critical factor in your flow meter’s performance. Whether you’re installing a simple rotameter or a high-precision turbine meter, mounting it correctly ensures you get the accuracy, reliability, and compliance you need.

When in doubt, consult your flow meter manufacturer and review product datasheets thoroughly. An improperly mounted meter can lead to significant operational and financial consequences.

Need Help?

If you’re planning a new installation or facing measurement inconsistencies, contact our team. We’ll help you determine the right orientation and provide expert recommendations tailored to your system.