Applying a flow meter requires matching technology to the application—considering fluid type, flow range, pressure, temperature, and accuracy needs—ensuring reliable measurement, process efficiency, and compliance with industry standards.

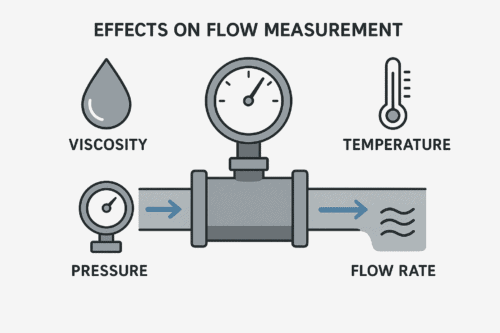

Viscosity

When applying a flow meter, fluid viscosity is a critical factor. High-viscosity fluids can increase pressure drop, reduce accuracy, or affect meter performance. Selecting the right meter ensures stable, reliable measurement, minimizes wear, and optimizes efficiency for applications ranging from lubricants to chemicals, food processing, and pharmaceutical processes.

Temperature

When applying a flow meter, fluid temperature must be carefully evaluated. Extreme heat or cold can affect meter materials, seals, electronics, and measurement accuracy. Choosing a meter with proper temperature ratings ensures durability, consistent performance, and reliable readings across demanding applications, from cryogenic liquids to high-temperature industrial processes.

Pressure

When applying a flow meter, system pressure is a key consideration. Excessive pressure can damage sensors, while low pressure may reduce measurement accuracy. Selecting a meter rated for operating and maximum pressures ensures safe operation, minimizes risk of leaks or failure, and provides reliable performance across industrial, chemical, and energy applications.

Flow Rate

When applying a flow meter, flow rate is fundamental to accurate selection. Each meter has a defined range; operating outside it can cause errors or damage. Matching meter type to expected minimum and maximum flow rates ensures precision, efficiency, and long-term reliability in diverse applications from water treatment to fuel measurement.