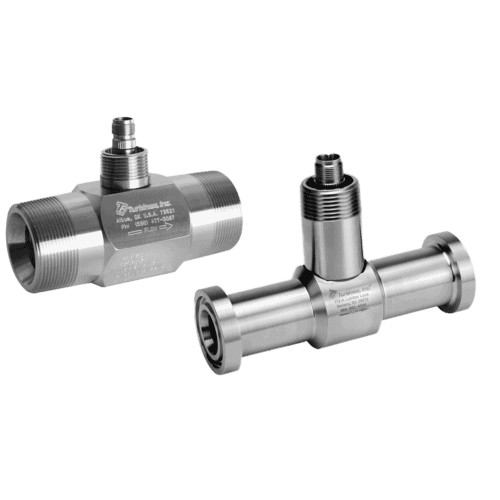

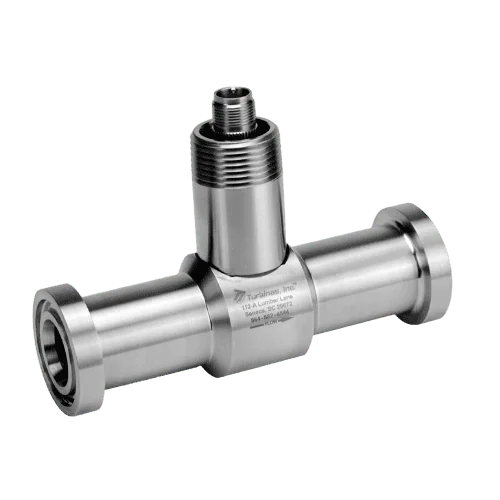

Hydraulic Flow Meters

Inline Petroleum Fluid Measurement Sensors

Turbines, Inc. manufactures flow meters designed for hydraulic fluids with flow rates up to 12,000gpm and pressures up to 20,000psi. Our hydraulic flow meters are engineered to safely and accurately measure fluids such as oil and other petroleum based media. These meters can be manufactured with various process connections including but not limited to SAE61/SAE62 (Code 61/Code 62), O-ring Boss, and the standard NPT.

Product Catalog

Need To See More Flow Meters?

View All ProductsNeed help finding a flow meter?

We can help guide you to the correct solution for your business needs, whether you are looking for product information, data sheets, repair information we are available to help!